The same trims can be applied to the remaining corners of the structure to complete the corner management process.įinally, the 7-inch diameter web members can be patterned to complete the design. The top corner will be defined the same as the first where the vertical members will be planner trimmed to the mitered horizontal members.

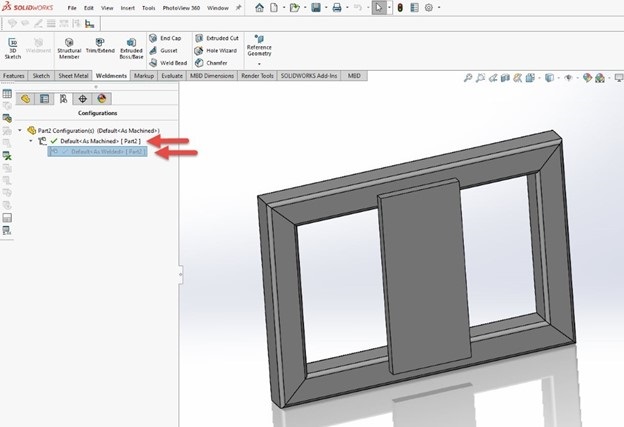

To simplify the manufacturing impact, the vertical member should be trimmed flat so it should be moved down to the planner trim racks.įor the next corner, we can see that the vertical tube has been automatically defined as a trim tool and the horizontal members get body trimmed to it. For this corner, we want the horizontal members mitered to each other and the vertical member trimmed secondarily. Initially, each member is mitered to each other. For the complex corners, there are more options. The simple corners will be set to body trim so they get coped to the vertical members. When you finish adding the structural members, the corner management tool is presented so you can fine-tune the corner treatments. Easy as that – another 12 members are added.Īt this stage, the members are defined but they are not trimmed. When selections are made, new members are added between the pairs located at the support planes. The chain option will be used to select the member pairs. In this case, the location of the new members will be defined by two support planes. Secondary members run between primary members and are defined by selecting member pairs. The web members will be defined using sketch segments and they will be 7-inch diameter round tubing. In this case, the vertical members will be changed to 10-inch diameter round tubing. In a structure system environment, members can have different profiles. Just like that, 36 members have been created. In this design, a window can be used to select the edges of the surface which defines 36 members without regards for member groups.įamiliar weldment profiles are used to specify the weldment cross section and for this selection, a 10×10 square tube will be chosen. Primary members are defined using 2D and 3D sketch segments: points, edges, reference planes, and surfaces. The new structure system is an advanced weldment environment that lets you create and modify structural members of different profiles in a single feature. Instead, it is defined with much simpler surfaces, sketches, and planes making it easier to define the layout of the structure. The definition for this new structure does not contain a 3D sketch. Let’s take a look at how this structure can be created using SOLIDWORKS 2019 weldments features. Weldments are a key feature of many designs and SOLIDWORKS has long been an innovator of providing tools to create weldments such as this structure to support the telescope in this Maunakea Spectroscopic Explorer.

0 kommentar(er)

0 kommentar(er)